Manufacturing installations

We can correspond to your problems such as automation of facilities, manpower saving, optimization, etc by our installations. We can correspond to your detailed requests with our know-hows cultivated throughout manufacturing internal our company.

We can deliver / maintain installations to overseas.

- What is ismart?

-

Multiple and physically independent machines and processes are gathered into one โBOXโ ,which can realize an integrated production line.

You can expect the production only with one ismart from raw material feeding to finished parts.

- Features of ismart

-

-

Space-Saving

Decrease of machine-space

Decrease of machine-space

Manpower-Saving

Decrease of number of machine operators

Decrease of number of machine operators

Speed and more efficiency

Decrease of moving of parts and in-process inventory, and number of times of machine changeover.

Decrease of moving of parts and in-process inventory, and number of times of machine changeover.

- image

-

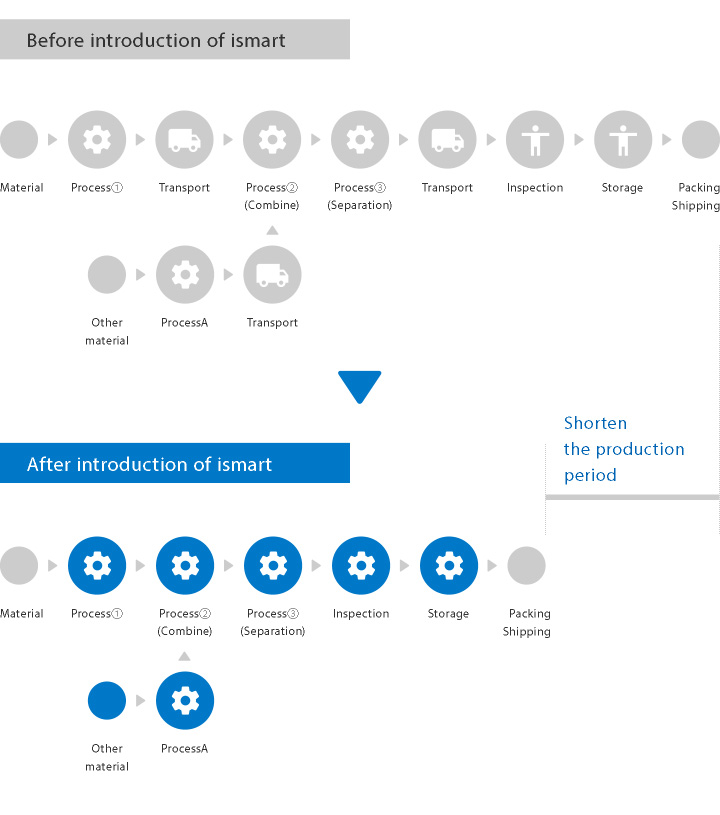

ismart-ize of process

ismart-ize of process

-

The other parts are combined to main-process flow and processed at Processโก , the finished parts come out.Composite processed products process

- Shortening of process and optimization by ismart(installation)

-

- Reduction of In-ProcessโTransportโ = moving , re-loading etc.

-

Continuous processing in installations

(You can do tact-calculation of processing time = Stable output) - You can check quality using the imaging equipment

-

Consistent flow production from production to storage

(Shortening the process)

(After processing, you can connect production-processes feeding

directly to installation, not directly transport)

-

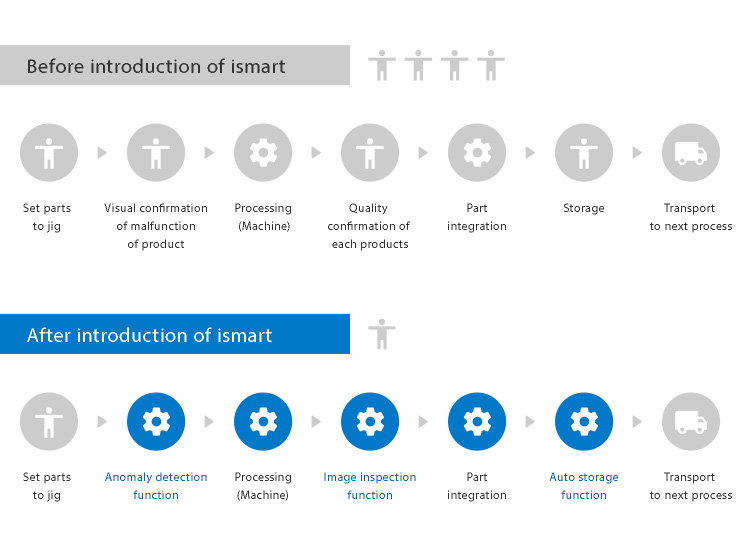

ismart-ize of function

ismart-ize of function

-

Automation of manual-process by ismart installation (from manual to machine)

+optimization by enhancement of functions

-

- Decrease of the number of operators

- Increase of production volume

- You can use factory space effectively, and can increase production lines.

-

You can simplify the work flow line.

= It leads to improvement of 4S and a reduction in workers' compensation accident

Inquiry

- Inquiries about ismart

-

Sales Department

Sales Department

Contact from here

Contact from here

Stamping Technology

Stamping Technology Manufacturing

Manufacturing Surface treatment

Surface treatment Precise mold parts

Precise mold parts